- Hardware Manuals

- Commissioning and Tuning Guide

- Software Reference

- Resources

If a drive needs to be replaced, these steps are required to ensure the same system’s behavior with the new drive.

In this document, the used configuration tool is OBLAC Drives. It can be used with an OBLAC Box or using a Virtual Machine.

All the parameters for a drive are stored in a config file. If a drive shows a fault and has to be replaced, this configuration can be exported and moved to the replacement drive. In some cases, the drive is completely broken and no connection is possible anymore. To prevent losing the configuration, it should be archived so it can be stored on a replacement.

The drive-specific commutation offset is also stored in the configuration file. Therefore, a specific config file is required for each drive.

If there are multiple similar motor drive setups with similar parameters, a common configuration file can be used. But in this case, the offset detection has to be done every time and can not be skipped.

Attention

Operating the drive with a wrong commutation offset can lead to uncontrolled and dangerous movements of a motor!

If no backup configuration file is available, neither archived nor from the old drive, a completely new configuration with the configuration wizard has to be done.

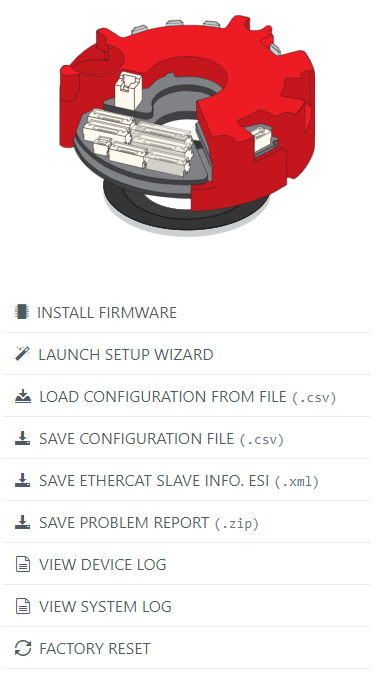

Underneath the drive’s picture on the main page of OBLAC Drives, different actions can be performed.

When clicking on “Save configuration file” a .csv file will be saved on the user’s PC that contains different EtherCAT SDO objects with their actual values.

This file can be used to back up a specific configuration.

Before replacing the node, please note the firmware version that is currently installed.

When replacing the node, please make sure to have the encoders properly connected to the same encoder port.

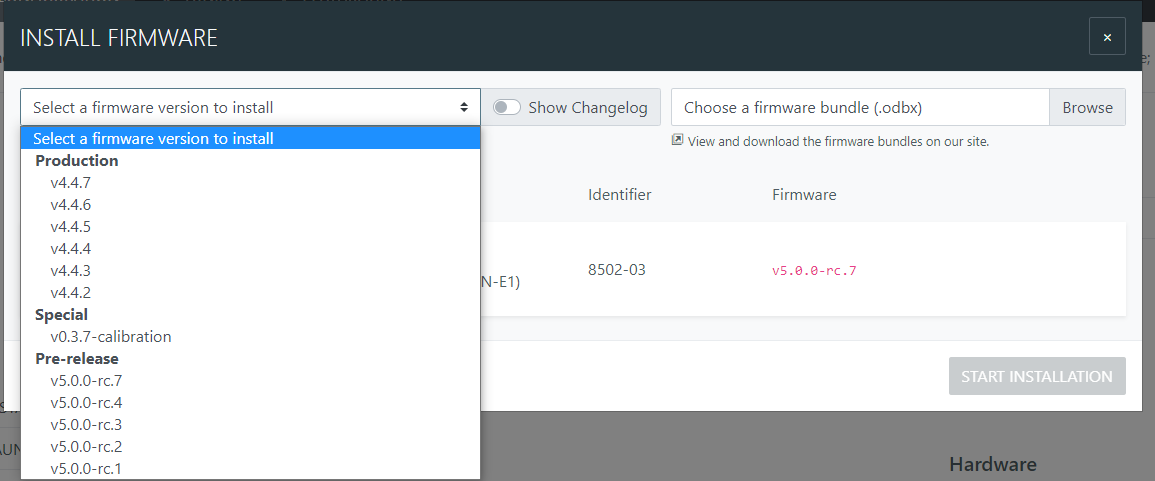

A firmware needs to be installed before the first commissioning of a new SOMANET drive. Please make sure to have the same or compatible firmware version installed as before.

The firmware update can be done online if the Virtual machine or the OBLAC BOX have internet connection, or it can be done offline through the firmware bundles that can be downloaded here

When clicking on the “LOAD CONFIGURATION FROM FILE” button, the following window will pop up. It contains all the objects that can be written from the .csv file to the drive’s memory. Please proceed by clicking on “LOAD CONFIGURATION” and wait until the procedure is finished.

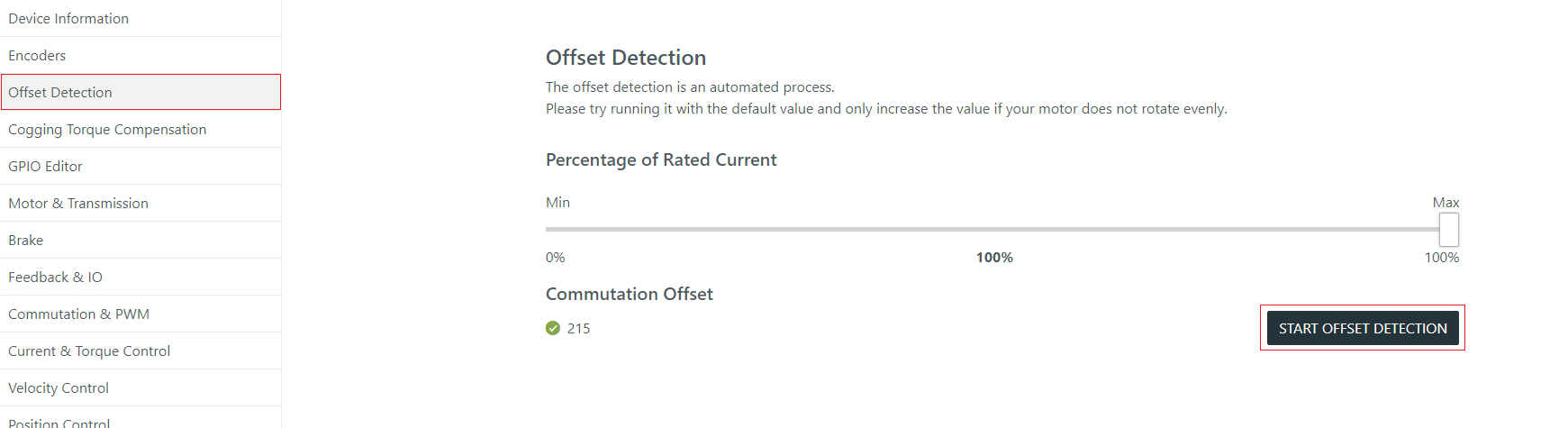

This step can be ignored, if the following points are true:

the motor phase’s order is the same as the previous drive

the motor encoder was not replaced

the encoder mounting was not rotated.

This step can be skipped if the previous step (Run offset detection) was skipped as well.

In case the offset detection was executed, please make sure to save the new parameters to the drive.

Saving configuration is done through the “SAVE TO DEVICE” green button in the top right corner of OBLAC Drives.

Underneath the drive’s picture on the main page of OBLAC Drives, different actions can be performed.

When clicking on “Save configuration file” a .csv file will be saved on the user’s PC that contains different EtherCAT SDO objects with their actual values.

This file can be used to back up a specific configuration.

After replacing Circulo, there is a small chance that the zero position moved more than the mechanical mounting tolerance. To detect this, a reference position is required.

Before replacing Circulo, please note down the firmware version that is currently installed.

Make sure the encoders are properly connected to the same encoder ports before replacing the servo drive.

When using the Circulo internal encoder disks, please take the nominal encoder distances into account.

The internal encoders have to be calibrated again to store the calibration data on the new drive. The calibration data is not stored in the config file nor somewhere else on the Circulo’s file system and can’t be moved from one to another Circulo.

Note

Update to the latest calibration firmware.

The commutation angle offset detection procedure has always to be executed.

If the configuration of the drive has a sharply tuned velocity controller, a smoothly tuned velocity controller is required for the encoder calibration. If there is no smooth velocity while calibration or if the calibration fails, the velocity controller has to be temporarily re-tuned.

To re-tune the drive:

Perform autotuning.

Set the velocity controller bandwidth to a value lower than 30 Hz and test the velocity controller.

Saving to the drive is not required, but the retuning will be lost after power-cycling.

Attention

Tuning the drive will lead to motor movements. Place your system in a position where these movements can’t damage anything. Please refer to the guidelines and restrictions in tuning in the motion control tuning part of our documentation.

check the phase error margin

When the calibration is finished, please update back to the production firmware.

Attention

The calibration procedure will move the encoder for 2 full turns of the calibrated encoder! Place your system in a position where these movements can’t damage anything. From OBLAC drives version 21.3.0 onward, the movement will be limited within the defined software position limits.

Attention

There is a small chance that the zero position of the encoder has changed after an encoder calibration. Therefore, an offset detection for the commutation and a re-referencing of the absolute encoder position are required after each calibration.

Install the production firmware with the same or compatible version of the original drive.

This step can be skipped if all the following points are considered:

the original configuration of the replaced drive has been loaded to the new Circulo

the encoder disks are not changed when Circulo was replaced

the phase order of the motor is not changed

But running the offset detection after installing the production firmware will always be the safest way.

Save to device after offset detection

Do some small movements in the playground. Start in torque mode to ensure a stable performance of the drive at the end of the replacement.

Verify that your zero did not move by checking the reference position. If the position moved or no reference position is available, you have to re-reference your system.